PRODUCTS

- Products

- Turbine Valve Actuator Tester (TVAT)

-

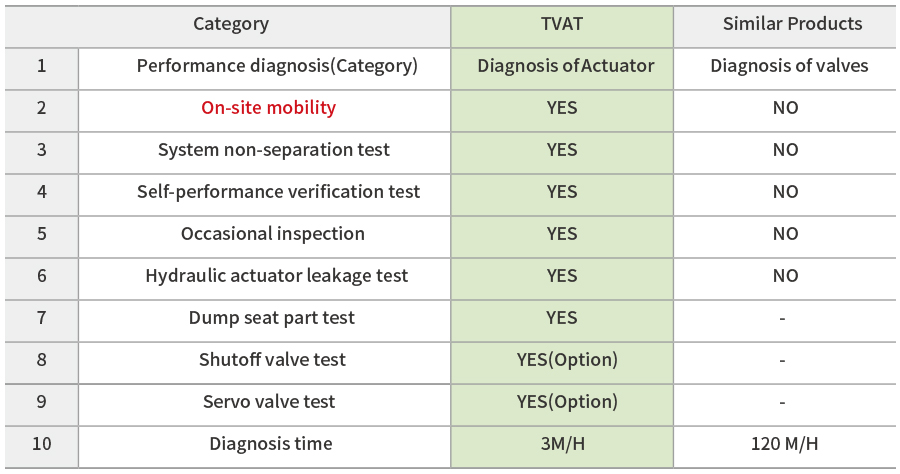

Differences from existing similar product technologies

-

Performance Prediction Diagnostic Tester (TVAT) for Turbine Valve ActuatorsActuator diagnostic 3D ImageContamination of hydraulic oil due to internal damage of actuatorNecessity of Performance Prediction Diagnostic Tester(TVAT) before malfunctioningDifferences from existing similar product technologiesPerformance Prediction Diagnostic Test-1Diagnosis of soundness by special diagnosis block modulePrediction Diagnosis Algorithm ConfigurationExpected EffectReal time failure prediction monitoring system(Option)

- Turbine Valve Actuator Tester (TVAT)

- Performance Prediction Diagnostic Tester (TVAT) for Turbine Valve Actuators

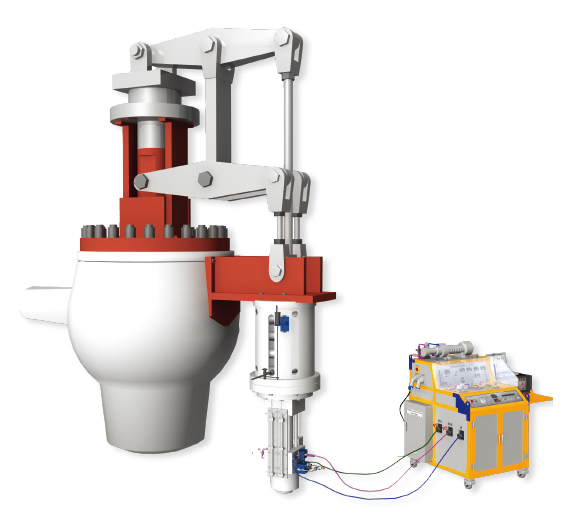

- Actuator diagnostic 3D Image

- Contamination of hydraulic oil due to internal damage of actuator

- Necessity of Performance Prediction Diagnostic Tester(TVAT) before malfunctioning

- Differences from existing similar product technologies

- Performance Prediction Diagnostic Test-1

- Diagnosis of soundness by special diagnosis block module

- Prediction Diagnosis Algorithm Configuration

- Expected Effect

- Real time failure prediction monitoring system(Option)

- Hydraulic System

- Vacuum System

- General Industrial Equipment

Differences from existing similar product technologies

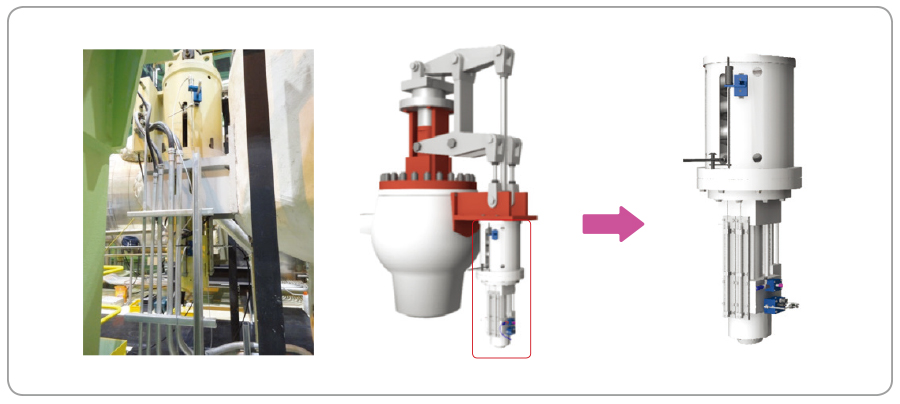

- A picture showing that it is currently possible for inspection only if it is separated from the system

There are various types of turbine steam valve hydraulic actuators

in power plants as shown below

in power plants as shown below

- In order to diagnose the performance of the hydraulic actuator, it is necessary to disassemble it from the system. And the process of maintenance is quite troublesome as it requires to move the actuator to an outsourced inspection service company for inspection which leads to huge maintenance cost.

- Since whole inspection for actuators in power plant is not feasible, some or all of actuators are being replaced in the planned maintenance cycle which delays the maintenance period and increase costs immensely.

A non-separating Performance Diagnosis using TVAT

- TVAT doesnŌĆÖt require disassembly of the hydraulic actuator from the system. It determines availability of continual usage for actuators. Furthermore, TVAT measures and analyzes the test results to secure the reliability of the power generation maintenance. TVAT is an innovative product that allows one to prevent malfunctioning factors of power plants by establishing a stand-by maintenance diagnosis system of power plants.

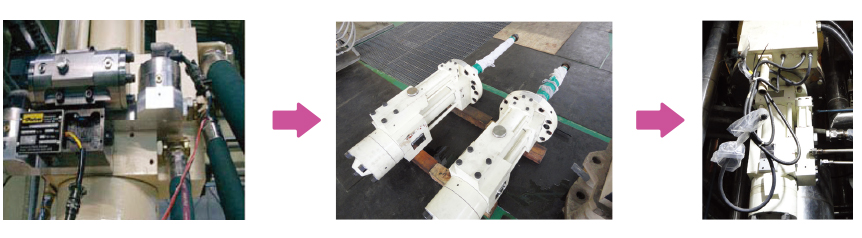

Differences from similar product technologies-2

- The current method is to test the hydraulic actuator by attaching the valves to the hydraulic actuator and supplying power to each of them, but the test results of this method include all leakage measures of servo valve, dump seat part and the main cylinder. Therefore, it canŌĆÖt measure accurate leakage of the actuator body which leads to ambiguous test data.

- It is not possible to test the performance of the actuator itself before installing the systemŌĆÖs warehousing goods and spare parts.

- In order to diagnose the performance of the actuator main body, it must be separated from the system and moved to the outsourcing company. Therefore, it is not possible to inspect all actuators within maintemance period.

- This portable tester has the key technology that enables performance diagnosis (application of predictive diagnosis algorithm) without separation from the system.

- In other words, it is possible to evaluate the integrity of the core device through the pre-inspection of the actuator body.

- Currently, the valve test device is a similar product. But it is a fixed type that is owned by an external company. It is necessary to disassemble the hydraulic actuator from the system and send it to the outsourced company for visual inspection.

- The diagnostic method used by the existing similar product doesnŌĆÖt allow performance diagnosis before the hydraulic actuator is disassembled from the system.

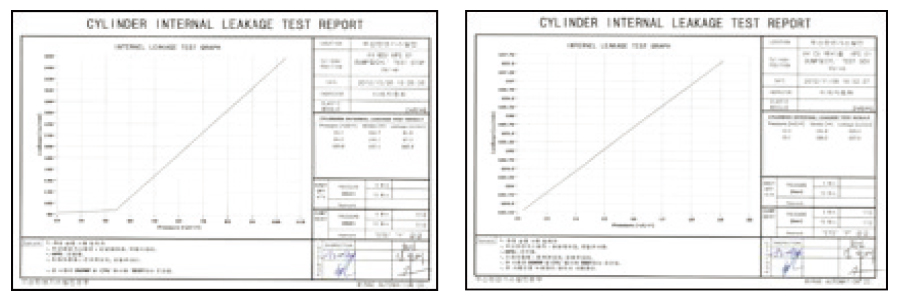

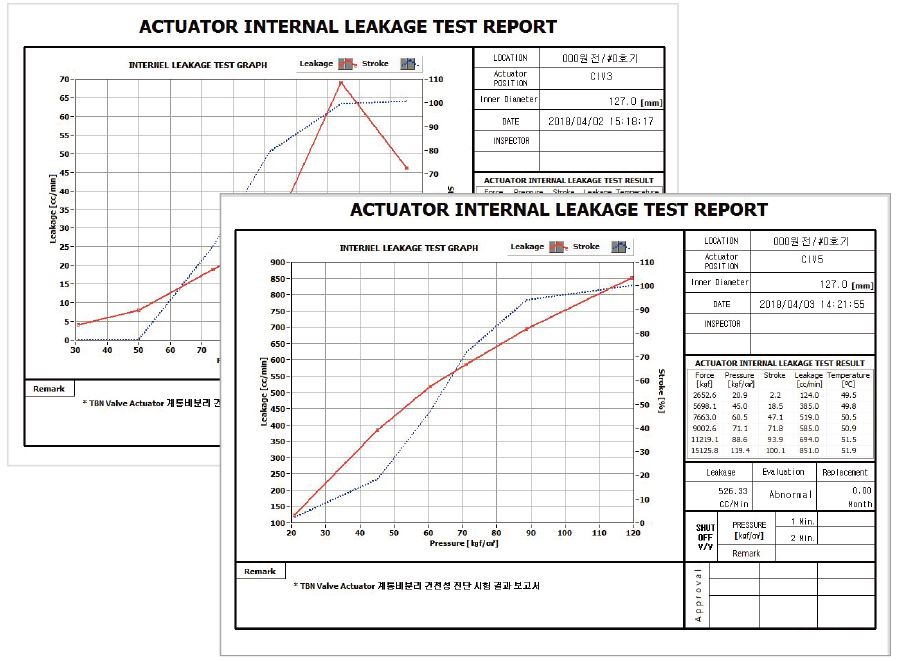

Cases of preventing malfunctioning factors in advance and diagnosis result report document

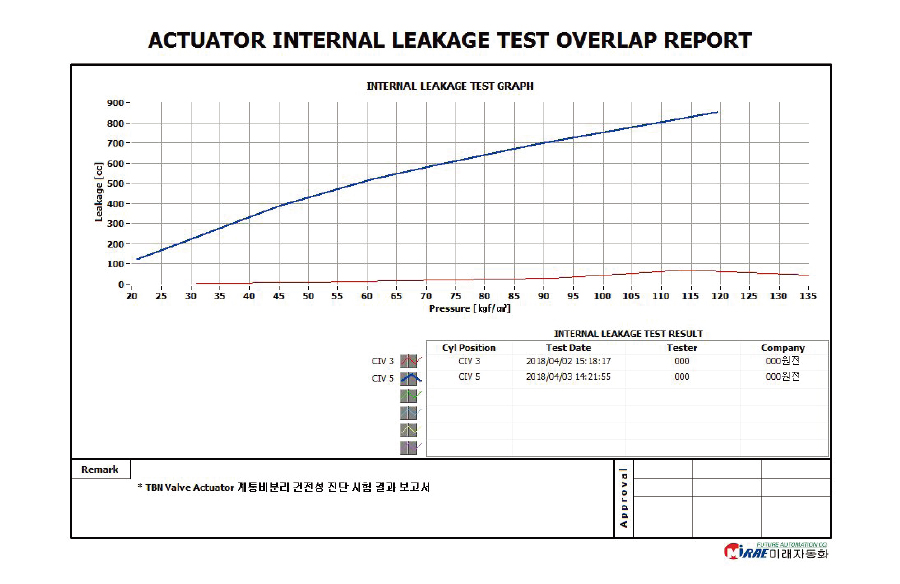

- Reference list and Actuator integrity result report example (from domestic power plants)

- Before & after Maintenance and Next Maintenance Cycle analysis(OVERLAP REPORT)

- Before installation of repaired actuators in the system, there was a successful case of actual prevention by filtering out inadequete (rejected) actuators after the performance verification test.